Plum contact product overview and design ideas

I. Product Overview

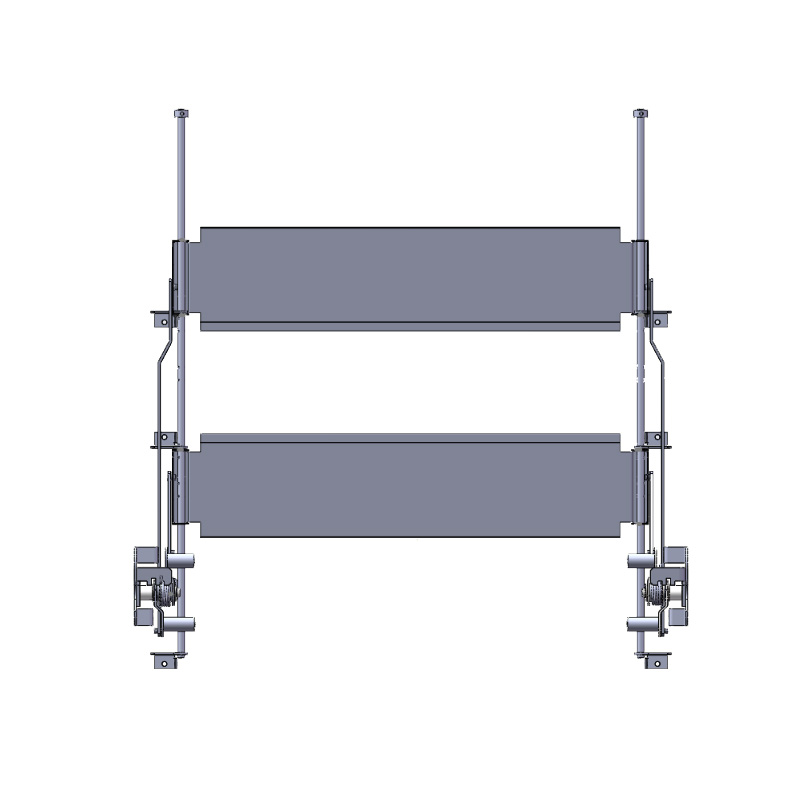

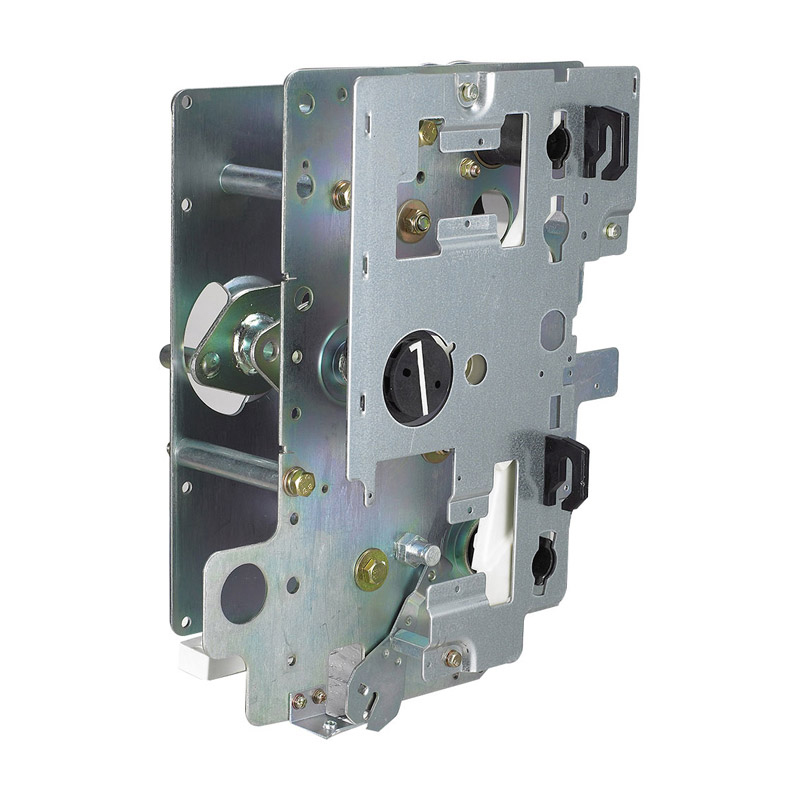

Plum contact is a kind of electric equipment accessories, because it is used in the primary circuit, so it is also called primary dynamic contact. The main body of the plum contact is made of non-magnetic stainless steel, which is used in the middle-mounted circuit breaker and other high-voltage medium-voltage electrical appliances, such as primary static contact should be dumped in ZN63 (VS1, VB1) and other middle-mounted circuit breakers.

Plummer contacts include contact support frame: tension spring, spring contacts, support frame is ring-shaped, a number of contact plates assembled on the support frame, forming a ring-shaped body, in the contact plates formed by the ring wall at both ends of the ring body are provided with a first contact and a second contact, two tension springs are mounted on the outer ring wall of the contact plates formed by the ring body and correspond to the first contact and the second contact, in the contact plates formed by the ring wall of the ring body immediately outside the first contact There is a first annular groove in the annular wall of the contacting piece adjacent to the first contact, and a first spring finger is embedded in the first annular groove; there is a second annular groove in the annular wall of the contacting piece adjacent to the second contact, and a second spring finger is embedded in the second annular groove. After the use of the structure, the plum contact in the conductive connection, on the basis of maintaining the original contact point, increased the contact point of the spring contact finger, thereby increasing the conductive contact area, greatly improving its conductive connection performance.

Second, the plum contact design ideas

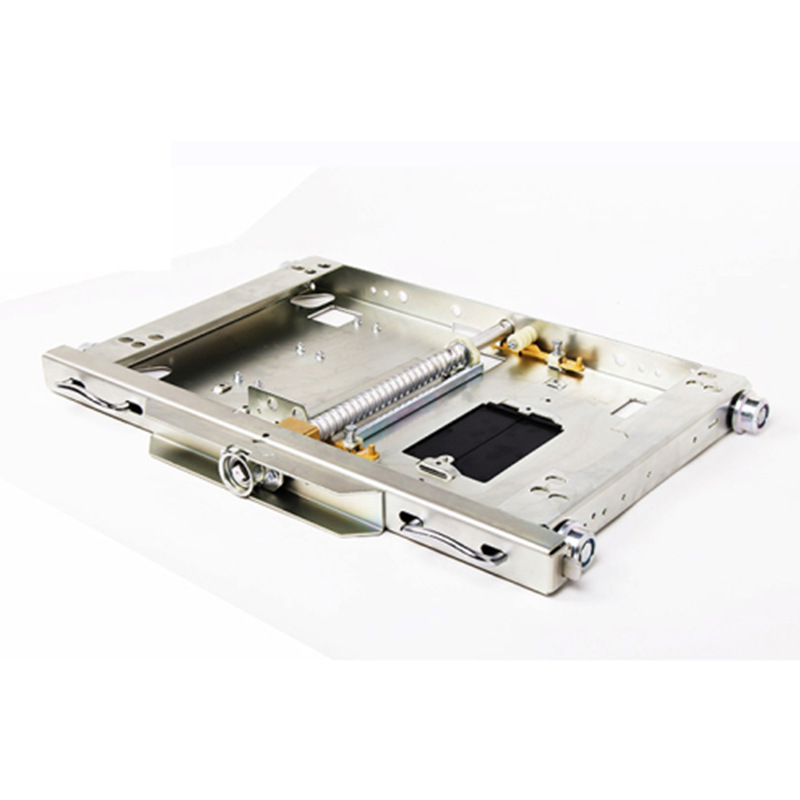

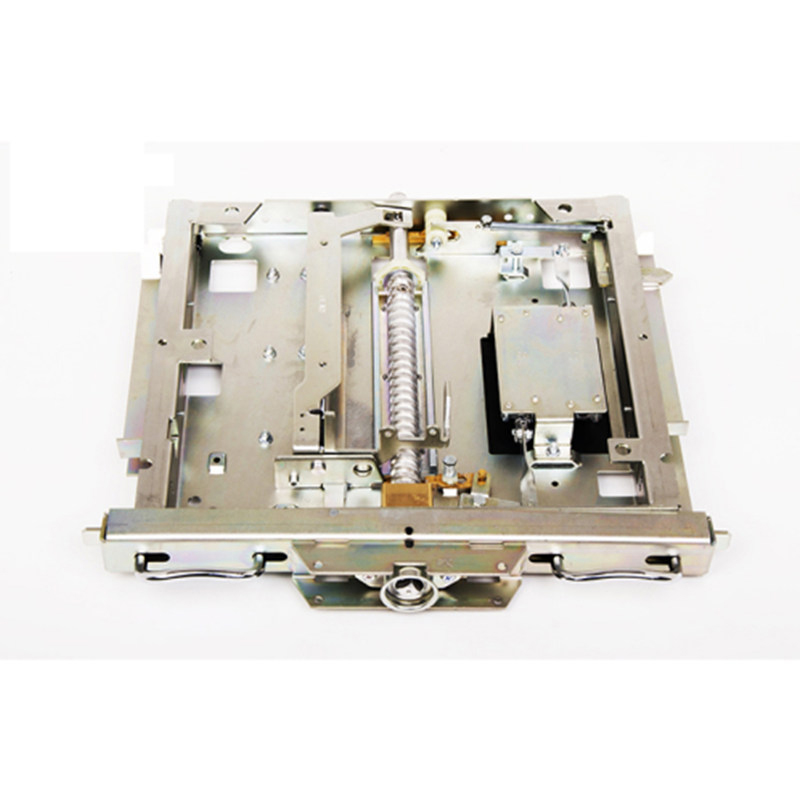

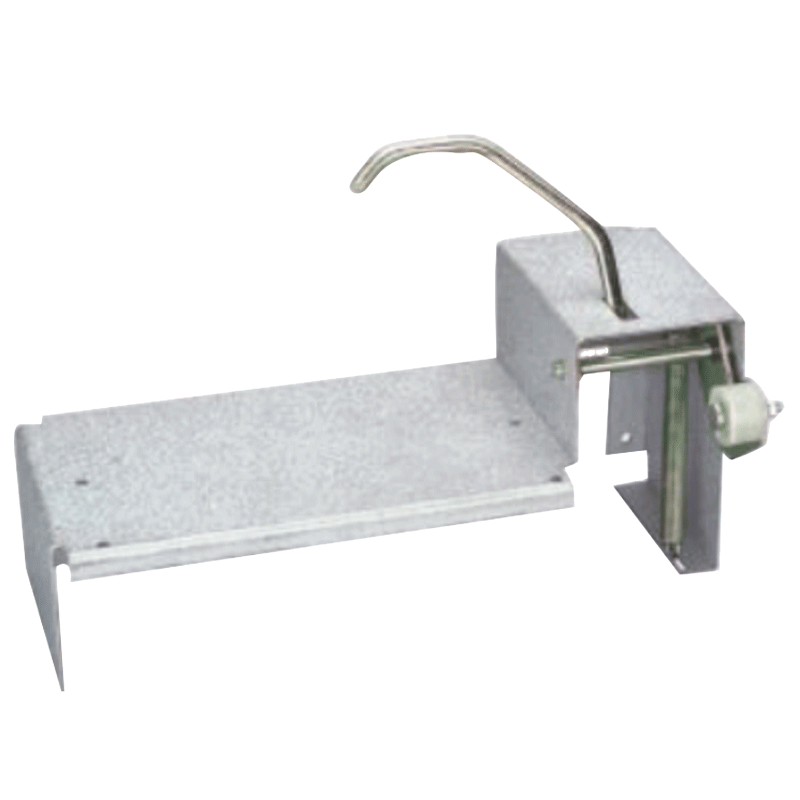

Electrical contact design process some matters needing attention to spring hoop, milling flap contact finger composition of the plum contact as an example, for the contact finger hoop spring position; contact finger rear end installation of insulating pad: milling flap finger inner circle and the difference in the size of the outer circle of the sole head and milling flap contact finger can be disrupted to use and so on, to analyze the methods to reduce the contact resistance of the contact finger. High-voltage switchgear in the case of a fault in the grid to open the fault current; in normal operation also to cut the load current, must have obvious breaking points, need to be equipped with divisible contacts. In addition, in order to facilitate the assembly of docking. High-voltage switchgear will also be set at the appropriate location to contact; in the moving part of the conductor body and the stationary part will also be set between the sliding contact. The contact surface resistance is present in both separable contacts, butt contacts and sliding contacts. The size of the contact resistance and its stability have a significant impact on the temperature rise of the switchgear over a long period of time and the dynamic thermal stability of the fault current impact. There are many factors that determine the size of the contact resistance, such as the surface condition of the contact, contact pressure, material hardness and material resistivity. Among the many factors, contact pressure is an important factor that varies widely and can be predicted by the designer's budget. The spring-loaded plummer contact consisting of a milled flap contact finger is an example of how to design and how to avoid going into the wrong direction. The so-called "milling flap contact finger", is the first contact finger outer corridor turned into a blank, and then use the milling machine will be milled into a flap of equal parts, becoming a piece of contact finger.

.jpg)